Cranbourne West’s Green Link Estate is a leading-edge industrial development in Melbourne’s south-east. A 79-hectare site featuring operational sustainability frameworks, plans for the estate have established a 6-star green rating with a range of environmental features.

This rating signifies one of the highest potential environmental ratings in the country and will serve the growing logistics needs of the region. Sustainable infrastructure is an integral part of the site’s future – with electric car charging stations, state-of-the-art building management systems, and the incorporation of extensive green spaces.

The master-planned estate includes parkland, walking tracks and bespoke landscaping – accompanied by expansive on-site wetlands to help meet biodiversity goals and the provision of local habitat for native flora and fauna.

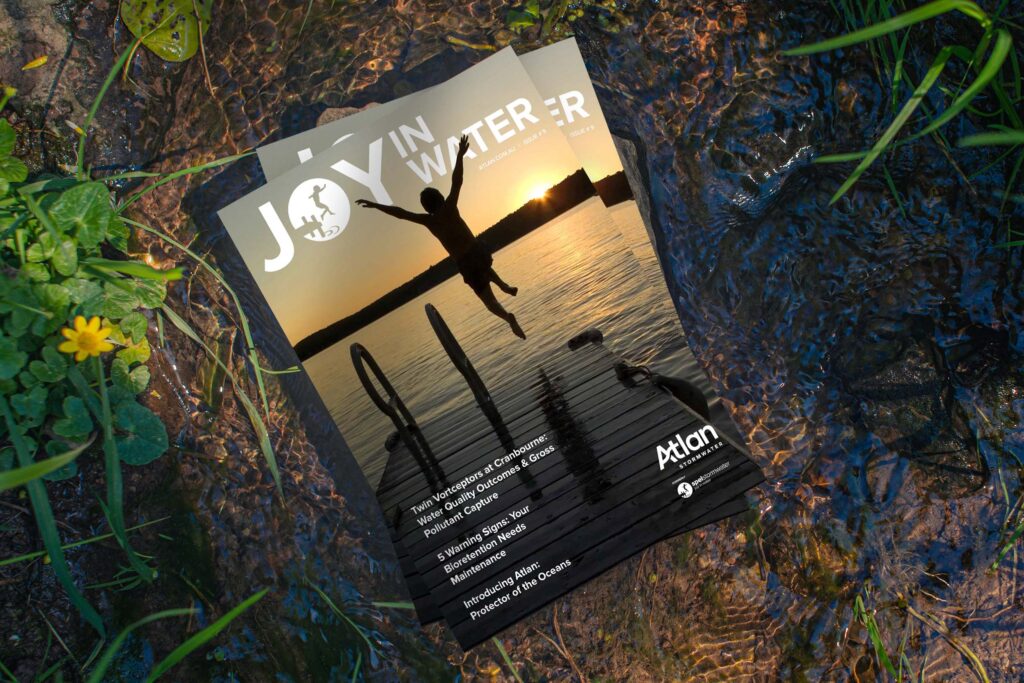

An essential aspect of on-site sustainability frameworks, stormwater treatment helps ensure it will meet important water quality objectives. We sneak a peek at the project in our latest video, presented by SPEL Stormwater’s Kurt Jensen.

Gross Pollutant Capture: Protecting On-site Wetlands

Stormwater solutions are key to the Green Link project’s approach to sustainability. SPEL was delighted to provide a unique dual GPT (Gross Pollutant Trap) configuration to help capture pollution conveyed by stormwater in the large industrial catchment area.

The crown jewels of this installation are two monstrous twin SVO 1600 Vortceptor units, which screen gross pollutants and other contaminants; which include debris, silt and nutrients across the large catchment prior to discharge into the nearby wetlands.

With tested treatment efficiencies of 99% Gross Pollutants (GP), 70% Total Suspended Solids (TSS), 30% Total Phosphorous (TP) – the high-performance capabilities of the Vortceptor will help ensure on-site water quality and WSUD (Water Sensitive Urban Design) best-practice.

A non-blocking hydrodynamic separation process, coupled with the self-cleaning screens of the Vortceptor, provides lower overheads across the service life of both units. The high flowrate capacity of the SVO 1600, and the tandem installation, are benefits of this scalable design – tailored to fit the demands of the large industrial site.

Accompanied by two 5×5 metre diversion chambers, the seamless installation of these concrete units was driven by a modular panel-style design and fabrication process. Combined with the single-piece fibreglass design of the Vortceptor, the result was a 5-hour installation supported by cost-efficient delivery, lifting and handling phases.

Sustainable Stormwater Outcomes

Carbon reductions for the Vortceptor’s FRP (Fibre Reinforced Polymer) design will provide 70% CO2 reduction over a traditional concrete GPT – an important point considering the site’s goal of achieving a net-zero carbon framework. A 25-year warranty is also a great boon for asset management.

Ensuring the treatment of outgoing stormwater runoff to capture a diverse range of pollutants – the dual Vortceptors will provide better environmental outcomes across the site. Epitomising our creed that ‘clean waterways are a right, not a privilege’, the installation is underpinned by a 50-year design life, with the resulting generational asset serving the community for many years to come.